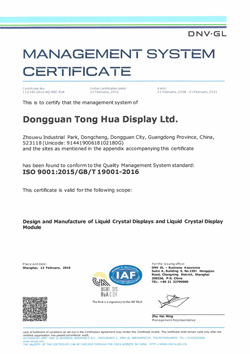

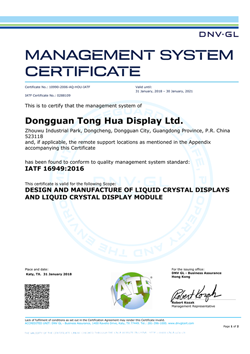

RCL Display Limited was certified by DNV for the ISO 9001 certification in 1997, ISO 14001 and TS 16949 certifications in 2006 and ISO 13485 in 2019.

In production process, we obey the IPC610 (level 3) standard.

The various quality standards and techniques being implemented are PPAP, AQL, Process FMEA, Design FMEA, Robust Design, TQM, SPC, R&R, Process Capability Analysis and Reliability Engineering. Our Quality Control Department is composed of IQC, PQC, FQC and QA divisions.

Our team of 150 well-qualified employees maintains and audits our quality system. Every product is thoroughly examined by the Quality Assurance Department before delivery. We have also introduced a series of LCD evaluation processes to keep track of the samples and finished products quality.

For instance, our quality control for automotive products is as following:

– Using automatic photo recognizer to defect missing segment, extra segment, etc.

– 300% Inspection ( Cosmetic & Functional ): Production, QA & PDI (Pre-delivery Inspection)

Quality Policy

Customer the First, Quality the First, Full Staff Participation

We satisfy our customer by meeting their quality requirement.

We develop our market by innovating technology & perfecting quality system.

We assure our quality by prevention & control — receiving, creating & transferring no defects.

We align ourselves by having participation of every staff in quality improvement.

All products are REACH, ROHS and Conflict Minerals provision complied.

Environment Policy

We prevent pollution & comply with regulations.

We establish EMS & implement it with training and communication.

We reduce wastage & involve everyone.

We protect & improve our environment.